Sustainably Manage Your Industrial Sludges with ESA

01 Apr, 2021 3:00 AM / by Cherie Poon

GIF Source: Environmental Solutions Asia — Feeding Sludge into a Hopper

At Environmental Solutions Asia, we sustainably manage your waste in our integrated biomimetic facilities. This includes one of our core plant capabilities — thermal processing of solid industrial wastes. This means that we are able to safely process waste streams such as Sludges, Waste Slurries, Filter Cakes, Spent Catalysts, Metal-bearing Dusts, and other Solid Residues from the Semiconductor, Pharmaceutical, Chemical Industries and more.

Video Source: Environmental Solutions Asia — Introducing Our Thermal Processing Capability

Not only do we carry out proper management of such waste to ensure zero harm to the environment, we enable the circularity of such resources. While the most convenient solution is to send such waste to the landfill, our clients partner us so that their waste is given a second lease of life. This is because we utilise green engineering and chemistry to sustainably recover metals and minerals from the solid industrial waste received.

And how do we do that? Here, we provide a step-by-step breakdown of our solid waste treatment process using Calcium Fluoride (CaF2) Sludge, or HF Sludge, as a case study.

Calcium Fluoride, also commonly known as Fluorspar, is a white chemical waste compound often generated by the Semiconductor and Electronics industry.

Step 1: Waste Collection & Hazardous Communication (if necessary)

Firstly, we collect your waste onsite by depositing them in open-top containers (OTC) or Jumbo Bags. The type of storage equipment used depends on the nature of your waste content, as well as the operational and space constraints at the point of collection.

Image Source: Environmental Solutions Asia — Open-Top Container (OTC) containing Sludge

While HF Sludge is no longer categorised as hazardous waste, other industrial sludges such as specific metal hydroxide sludges would require expertise in Hazardous Waste Management. In such cases, proper labels will be employed to inform our workers and all other stakeholders of the potential hazardous risk of the waste.

The waste is then carefully loaded onto our trucks and safely transported to our facilities. All our drivers are equipped with a valid HTDP1 license while our workers undergo in-house Safety Induction Courses to be equipped with the knowledge to handle hazardous wastes.

Step 2: Pre-treatment Design & Lab Analysis

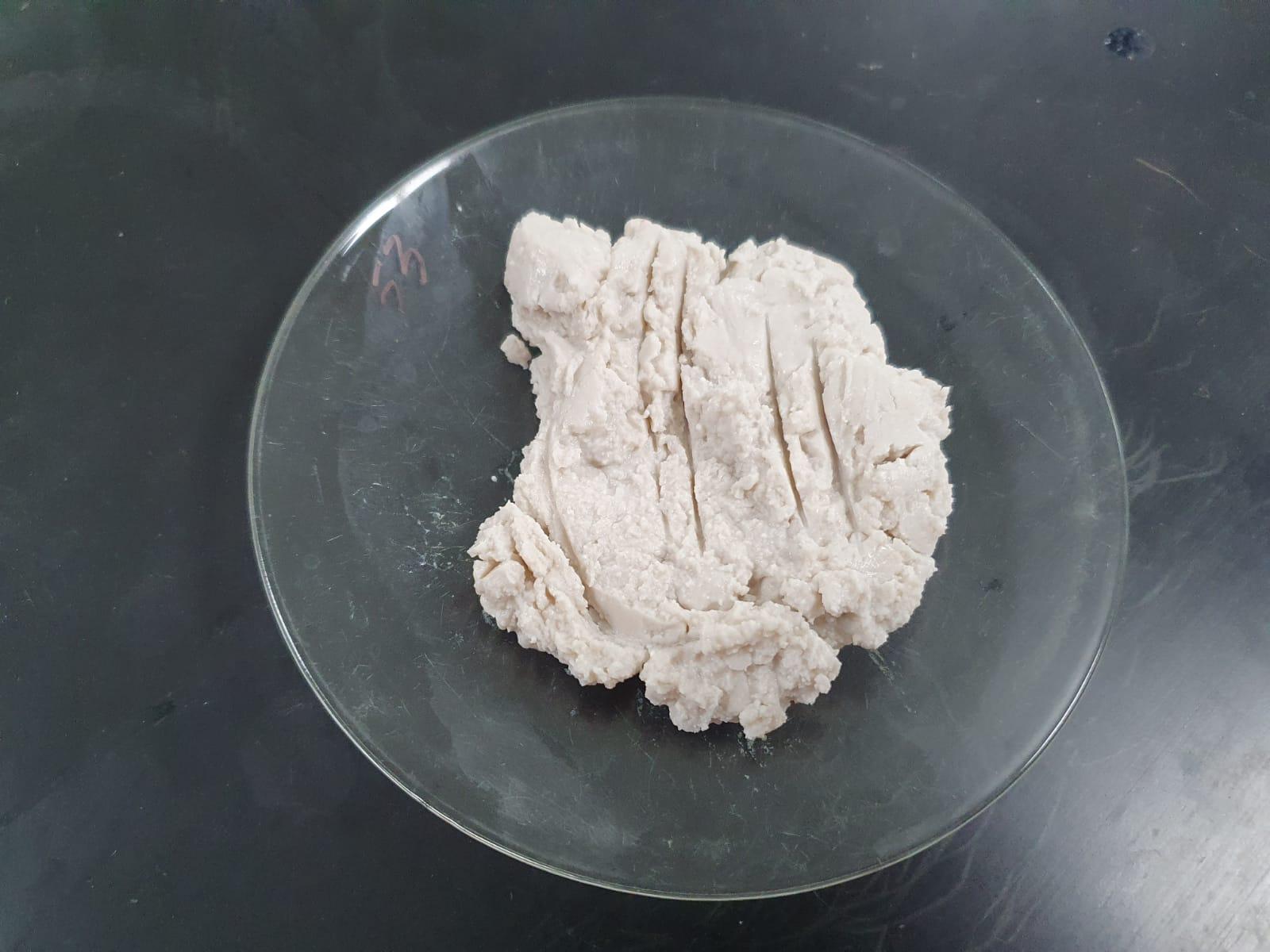

Image Source: Environmental Solutions Asia — Lab Analysis of HF Sludge Sample

Once the wastes reach our facility, they will be weighed and recorded into our proprietary waste tracking system – AURIC. Samples for each collection are taken to our in-house chemical lab to conduct analyses for moisture, element composition, and metal precipitation. These routine tests help ascertain content and quality of the waste.

Image Source: Environmental Solutions Asia — HF Sludge before Thermal Processing

Based on the lab results, our engineers will determine the suitable treatment process for the waste. In this case, HF Sludge would need to undergo thermal processing. These instructions will be passed on to our Production team who will ensure all wastes are properly stored until they can be processed.

Step 3: Thermal Processing of Sludge in Paddle Dryer

GIF Source: Environmental Solutions Asia — Conveying HF Sludge into the Paddle Dryer

Next, this process continues at our thermal processing machine, also known as the Paddle Dryer. It is an enclosed chamber that heats and pulverises sludge. This process reduces the moisture content of the HF Sludge by up to five times. Any flue gas produced during this process is treated by scrubbers before being discharged into the atmosphere.

Image Source: Environmental Solutions Asia — Shredded Wood Waste (From Pallets) for Gasification

In line with our mission to integrate circularity into our facilities, we gasify wood waste as a source of renewable energy to power our thermal processors. This serves as one of our facility’s core drivers of sustainability, as we minimise energy pulled from the power grid. By opting to use renewable energy, we reduce our reliance on electricity derived from fossil fuels.

Step 4: Remanufactured Minerals or Chemicals Packed & Prepared for Sale

GIF Source: Environmental Solutions Asia — Pulverised Fluorspar deposited into Jumbo Bags

Finally, these resultant products are subsequently packed into Jumbo bags for sale locally or export overseas. In the case of HF sludge, we remanufacture it into synthetic Fluorspar. This chemical compound can be used as steelmaking Fluorspar in smelting plants or a pulver fluxing agent.

Image Source: Environmental Solutions Asia — Jumbo Bags containing Fluorspar

Partner with us to enable the circular economy today

Want to know how you can sustainably manage your industrial sludge wastes too? We currently provide our thermal processing services to partners from the Semiconductor, Petrochemical, Electroplating, and Wastewater Treatment industries and more.

Get in touch with us at +65 6653 2299 (Tel), drop us an email at info@env-solutions.com, or fill in the inquiry form on our website. Alternatively, you can click here to find out more about our other services.

1 Hazmat Transport Driver Permit – A course to equip participants with the knowledge to transport hazardous materials safely & to respond to emergencies. https://avanta.com.sg/page/courses/hazmat-transport-driver-permit-htdp-course/

Topics: Reimagining Sustainability, Sludge Solid Industrial Waste, Sustainability in Singapore

Written by Cherie Poon