Recycling VS Mining

20 Jul, 2020 12:00 AM / by Quek Leng Chuang

How climate friendly are recycling operations?

Carbon Dioxide

Recycling is, indeed, energy intensive. For the recycling of base and precious metals, high temperatures and chemical procedures are required in order to conduct them successfully.

This is also why recycling is the last step in the Zero Waste approach. Still, recycling base and precious metals from toxic and hazardous waste or e-goods is crucial. It enables us to establish a circular economy and to close the loop between discarded products and new raw materials. But how do recycling operations perform in terms of carbon dioxide in comparison to the use of “raw” materials? In this article, we outline the carbon footprint for recycled and mined metals.

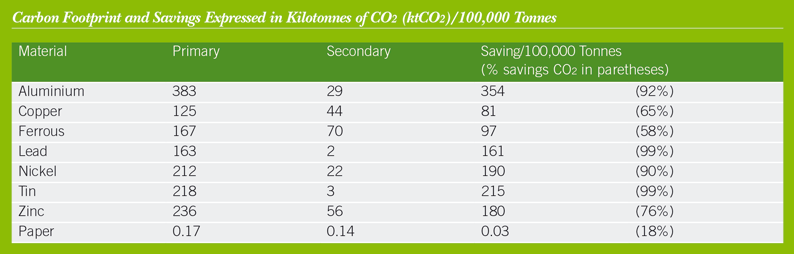

In terms of carbon dioxide emissions, recycled base and precious metals always show a more favorable balance than mined ones. This is shown in a report of the Bureau of International Recycling (see table below).

Report on the Environmental benefits of Recycling, Grimes, Donaldson & Gomez, 2008. p.4

This clearly shows that recycling operations always generate less carbon dioxide than natural mining operations. Savings are extremely high, ranging from 92% for aluminum and 99% for tin to 65% for copper. This savings get even higher when recycling companies employ a low carbon approach in their operations. As we power our business operations with renewable energies, we can even achieve a negative carbon footprint. The more often metals are recycled and not mined, the lower their carbon footprint. Luckily, most metals can be recycled unlimited without quality compromises.

For easier calculation, the table above starts to measure the carbon footprint of naturally mined metals only when ore is delivered at production plants. This means that carbon emissions from ore extraction and transportation to the facility is not even included! In industrial mining, heavy machines use remarkable amounts of energy and thus add to the carbon footprint of those metals. For recycled metals, the calculations in the table start when secondary material is delivered to a recycling factory for further processing.

The numbers given in the report are just a few examples of savings we can make when conducting recycling operations instead of extracting metals from natural mining. All in all, recycling has a remarkable potential to lower down the carbon footprint of our planet. Carbon dioxide saved by recycling operations amount to 1,8% of global fossil fuel emissions alone in 2008 which is equal to all the emissions issued by the airline industry in this year. When scaling up worldwide recycling operations for base and precious metals, we can also lift pressure from the environment in terms of chemical use, soil degradation and commodity exploitation.

Find our more about our base and precious metal recycling operations and if you’re ready to recycle your waste, get in touch with us today.

Topics: Carbon Neutrality, Carbon Offset, Catalytic Converters, Corporate Social Responsbility, Environmental Offset, Metal Waste, Reimagining Sustainability, Sustainability in Singapore

Written by Quek Leng Chuang

LengChuang is a chemical engineer and an expert in carbonomics. He is the founder and owner of Environmental Solutions (Asia) Pte Ltd.