Singapore’s Circular Economy – Pipe Dream or Pragmatic Solution?

04 Mar, 2021 6:56 AM / by Valerie Koh

COVID-19 has revealed tremendous gaps and inadequacies in our existing systems — salient issues that we need to address if we want to reimagine a stronger and more resilient post-pandemic world. By greening our systems, Singapore can start to pave the road to recovery and safeguard ourselves against future global disruptions.

The recently-announced Green Plan 2030 is a welcomed move for industries, consumers and the third sector alike. This is a multi-agency development agenda that charts out targets for our nation to achieve by 2030, with a view to align with our national goals set under the United Nations 2030 Sustainable Development Agenda as well as the Paris Agreement. Chiefly, the plan aims to halve Singapore’s 2030 peak emissions by 2050 and achieve net-zero carbon emissions as soon as viable.

While the Green Plan 2030 covers five different pillars, we thought to delve into two areas related to ESA’s expertise as a business driving the green economy. Inspired by the Green Plan 2030, this three-part series will delve into three aspects — namely the Circular Economy, Clean Energy, and Sustainable Living.

In this article, we will be addressing the Circular Economy.

What’s the circular economy about?

Based on a study by Ellen MacArthur Foundation, the circular economy, i.e. designing out waste, keeping materials in use, and regenerating farmland can reduce emissions by 9.3 billion tonnes (equivalent of current emissions from all forms of transport worldwide).

With the ultimate goal to reduce our disposed waste by 30% by 2030, resource circularity has become an emerging topic in recent years. The Circular Economy is a move away from the traditional take-make-waste linear model to one that channels end-of-life resources back into production to eliminate waste. Some are calling this the cradle-to-cradle approach.

This is a concept that is neither new to Singapore nor the newly announced Green Plan. Our Circular Economy goals are a reiteration of what has been mapped out in Singapore’s Zero Waste Masterplan, a national blueprint with key strategies to tackle waste management more sustainably. As some of us might already know, we have closed our water loop. Now, we hope to close other material loops too.

What does it mean to close the loop?

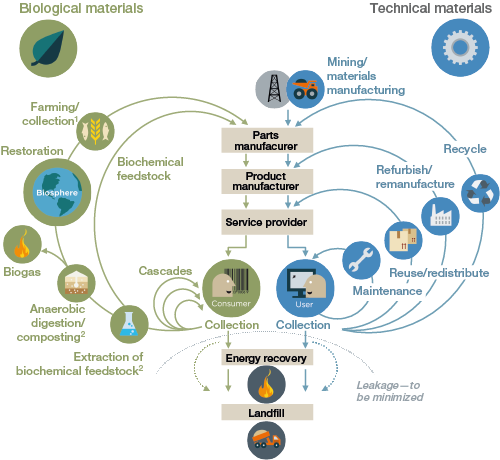

Before we delve into the different material types, we need to establish what it means to close the loop. A reasonable person would associate that with recycling. However, if we were to turn waste into energy (WtE) through incineration, would that be a form of recycling? This graphic taken from the World Economic Forum shows that energy recovery is a distinct concept from recycling.

Source: Ellen MacArthur Foundation circular economy team drawing from Braungart & McDonough and Cradle to Cradle (C2C)

Yet, if we were to look at NEA’s statistics, the use of wood and horticultural waste as fuel in biomass power plants is categorised as a form of recycling. Similarly, at ESA, we recycle our wood by gasifying it to produce energy. So, what is the difference?

In an ideal world, all recyclable materials would be recycled in a closed-loop. Thus, all plastic products can be turned into plastic products again, with limited deterioration in quality. However, in most cases, this is not the case due to several reasons.

Firstly, the oversupply of virgin raw materials at low prices often means that recycled raw materials do not make their way into industrial manufacturing plants and thus final plastic products. However, this is changing.

Another challenge is that often products aren’t designed with recyclability in mind. Hence, it becomes more energy-efficient to recover energy from it than to recycle it.

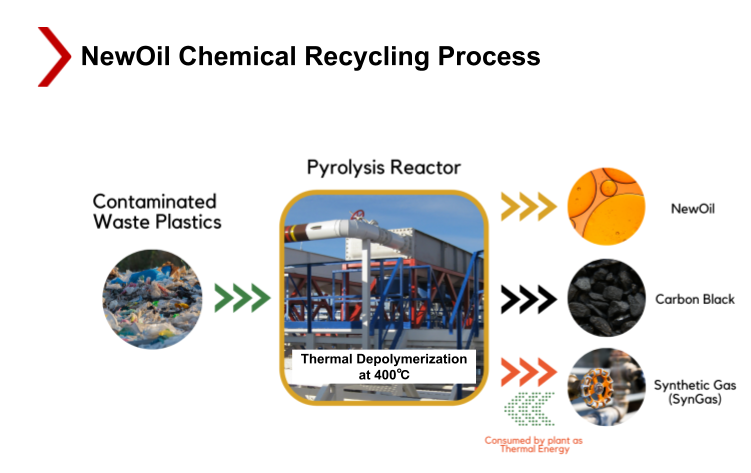

Thirdly, not all energy recovery or WtE systems are created equal. It is important to understand the differences between incineration and other forms of WtE technologies such as pyrolysis or gasification. Each of them has different levels of energy efficiencies, CO2 savings, and economic cost savings – as such it is important to evaluate the nuances between different types of WtE technologies before we conclude.

So, the answer to the question posed? As much as possible we should aim for closed-loop recycling while remaining open to efficient thermal recovery methods as one of the tools in our circular economy toolbox.

What other material loops can we close?

We will dive into three materials – Plastic, Wood, and Sludge & Ash in this article.

1) Plastic Waste Loop

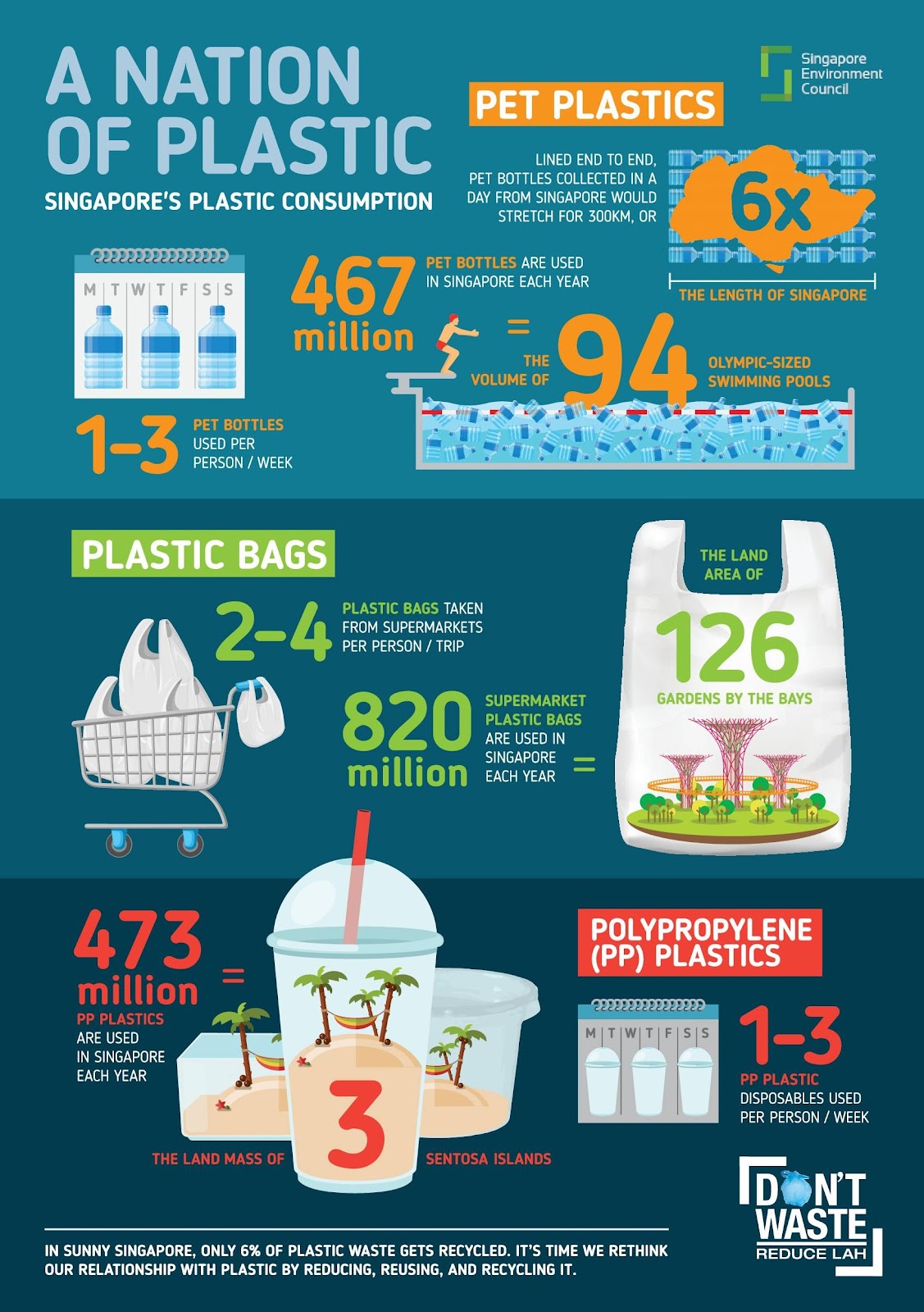

We use nearly 1 million MT of plastic each year and only 4% of this is recycled. However, NEA has recently announced that they have awarded a tender for a plastics recovery facility in Singapore. This facility will mechanically recycle PET bottles as well as sort and identify plastic waste for chemical recycling.

Study by SEC: https://sec.org.sg/wp-content/uploads/2019/07/DT_PlasticResourceResearch_28Aug2018-FINAL_with-Addendum-19.pdf

Another key development is the Mandatory Packaging Reporting (MPR), an initiative that acknowledges producer responsibility and designs out waste upstream of the supply chain. This was enacted under the Resource Sustainability Act in 2020. This will require generators of plastic waste to report their waste volumes and plans to reduce waste generation.

In view of these developments, we are making good strides towards developing an enabling ecosystem to close the plastic waste loop. All companies are expected to report their waste volumes by 31 March 2022 in accordance with the MPR. This is a significant step as it will provide a clearer picture of the sources, types and volumes of large plastic waste streams — allowing industries to figure out how best to build technologies and value chains to close this plastic waste loop.

And how are circular economy businesses currently closing the loop in Singapore?

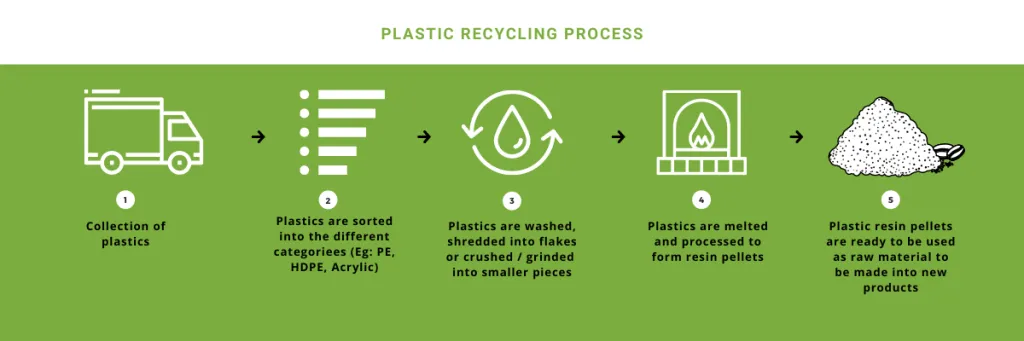

- Local Mechanical Recyclers

Plastic mechanical recyclers like Ravago and Gee Hoe Seng take in relatively clean plastic waste to be further processed into plastic resin or recycled post-consumer plastics.

Source: https://www.ghs.sg/recyclables/plastic-recycling/

- Local Chemical Recyclers

Chemical recycling is an emerging solution to treat plastic wastes that are not suitable for mechanical recycling, which often end up being incinerated. These include contaminated plastics and mixed plastics. Currently, ESA is the only chemical recycling facility in Singapore.

Source: Environmental Solutions Asia

- Local Plastic Traders

Other recyclers such as V1recycle aggregate and sort waste plastics into bales for recycling overseas. These plastics are often relatively clean and of consistent quality, which makes it economically viable to sell to other plastic traders and recyclers in the region.

- Other Technology Providers

There are also start-ups which have turned plastic waste into construction materials. For example, Magorium has a technology to turn shopping bags, plastic bottles into a substance that can be repurposed into road materials.

2) Wood Waste Loop

Singapore generated more than 400,000 MT of wood waste last year and 66% of this is recycled. This means 34% of this material can be better recovered.

Based on our experience, wooden pallets, planks and crates from industrial clients are often recycled. This is because it costs a minimum of $77 per ton to incinerate waste wood while recyclers only charge 30% – 60% of that price. Thus, it makes economic sense for companies that generate a large amount of waste wood to recycle it.

And how are circular economy businesses closing the loop in Singapore?

- Local Wood Recyclers

LHT, the first wood recycler in Singapore, produces technical wood from waste wood. They are able to manufacture recycled wood that can be used for furniture, flooring, building material, and heavy-duty industrial applications. Currently, LHT is able to process 30,000 MT of wood each year.

- Upcyclers

Creuse, an offshoot brand of a local pallet and packaging supplier, upcycles wood waste into functional products such as coasters, stools and crates. This means that the lifespan of these wood wastes are extended as they are repurposed to enter a new life cycle.

- Recyclers (focusing on energy recovery)

When wood, a form of biomass, is combusted and gasified, heat is released, which can then be used to generate electricity. Currently, ESA has the capacity to gasify waste wood to power all our plant processes.

- Other technologies

A group of researchers at the National University of Singapore (NUS) have incorporated biochar from recycled wood waste into mortar and concrete mixtures, resulting in stronger and more watertight building structures. This form of recycling translates to around 6 tonnes of wood waste recycled a typical 4-room HDB unit with a 100sqm floor area.

3) Sludge & Ash Waste Loop

Singapore generated more than 200,000 MT of ash & sludge waste last year and 10% of this is recycled. This means 90% of this material can be better recovered.

The good news is that there are plans from PUB to turn sludge into biogas using another WtE technology – Anaerobic Digestion. This biogas will be combusted to power the new waste treatment plant (a part of Tuas Nexus) which will be completed in 2025.

And how are circular economy businesses closing the loop in Singapore?

On the other hand, the local infrastructure for resource recovery from industrial sludges could be improved. Sludges that have significant volumes like Calcium Fluoride Sludge from the semiconductor industry and Metal and Hydroxide Sludge from the wastewater treatment industry are predominantly stabilised for disposal or further processing overseas instead of recovery locally.

And why is that so? This is because such waste is varied and complex which makes the recovery of metals or minerals from sludge technically challenging. In our experience recovering metals and minerals from sludges, different sludges warrant different extraction technologies due to factors like metal composition and yield of recovery. Not to mention, these factors also have to be balanced against economic feasibility, as different metal types generate varying revenue. Thus, more investment or collaboration is needed to enable the circular economy.

Against this backdrop, it is useful to note that more manufacturing plants are adopting Zero Waste Goals, which is a step in the right direction towards a more sustainable material management approach.

Summary

Singapore has closed our water loop and found ways to improve our relationship vis a vis the environment amidst rapid urbanisation. We believe there is great potential in our country leading the charge in enabling, building and setting the standards in this green economy. As a green business involved and invested in advancing the Circular Economy, we are heartened by the Green Plan’s vision for circularity.

We believe that the Circular Economy is within reach, but that requires developing a deep and accurate understanding of the different waste loops in our ecosystem. Our take is that the waste landscape is multilayered and that there multiple ways to go about innovating circularity and investing in synergistic collaborations between different players. We hope this article has offered insights into Singapore’s endeavours to close waste loops, including existing efforts, limitations and considerations when it comes to recovering our plastic, wood, and sludge waste.

Topics: Reimagining Sustainability, Sustainability in Singapore

Written by Valerie Koh

Valerie advocates for a kinder and more inclusive form of capitalism. She is the Assistant Manager (Sustainability & Marketing) at Environmental Solutions (Asia) Pte Ltd.