Sustainably Manage Your Spent Acids with ESA

24 Jun, 2021 1:31 AM / by Quek Leng Chuang

At Environmental Solutions Asia, we enable the circular economy of specialty chemicals and minerals. Our operations in Singapore help clients in the Chemical, Electroplating, Pharmaceutical, and Semiconductor industries sustainably recover or safely dispose of their chemical waste. We are able to process and recycle spent acids*, alkalis, plating solutions, etchants, solvents, and other spent chemicals.

Since chemical waste is hazardous if leaked into the environment, we take our clients’ chemical waste and transform it safely every step of the way — from collection to disposal or recycling and sale of technical grade products. Our sustainability goal is to apply green engineering and chemistry to find the most energy-saving and cost-efficient way to give these spent acid and alkali waste a second lease of life.

In this blog post, we provide a peek into our sustainable process of physical-chemical treatment. In this process, we transform hazardous waste products (Spent Hydrochloric Acid and Calcium Hydroxide Sludge) into a useful chemical product (Calcium Chloride solution).

Step 1: Waste Collection using Hazardous Waste Expertise

We begin by collecting Spent Hydrochloric Acid and Calcium Hydroxide Sludge at our client’s site. The spent acid is transferred into an ISO (International Standard Organization) tank unit or an Intermediate Bulk Container (IBC) while sludge is placed into jumbo bags and safely delivered to ESA quarters.

During transportation, we employ best-in-class safety practices. For example, our vehicles are fitted with the necessary hazcom labels and fail-safe mechanisms to mitigate risks of leakages. And our field staff are equipped with the right protective gear as well as professional safety training to handle and transport such hazardous waste.

Image: Environmental Solutions Asia — Our ISO Tank

Step 2: Pre-treatment Design & Lab Analysis

Once the wastes reach our facility, they will be weighed and recorded into our proprietary waste tracking system – AURIC.

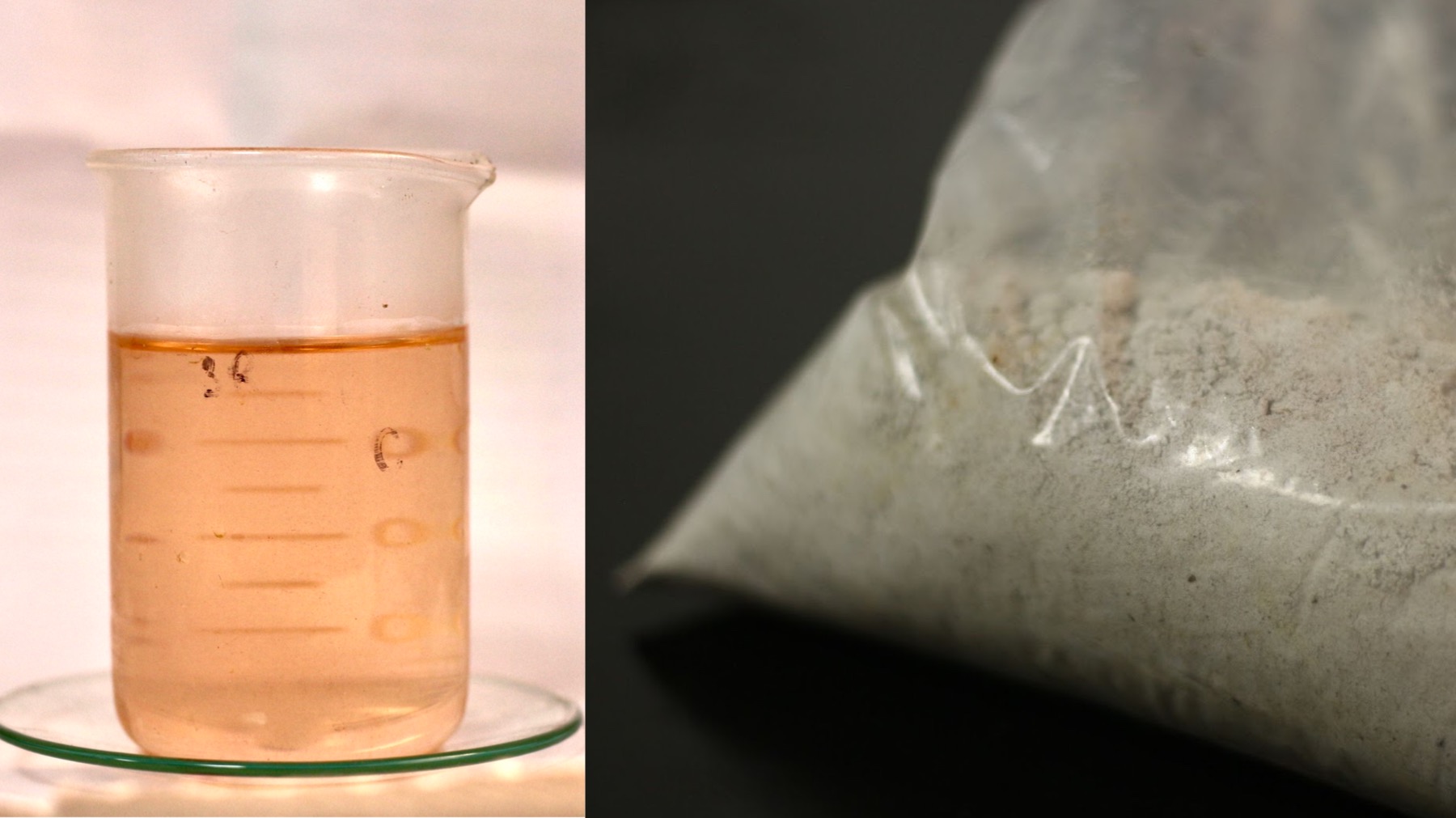

Samples for each collection are taken to our in-house chemical lab to determine its level of purity. This allows our green chemists to determine the optimal ratio of Spent Hydrochloric Acid (HCl) and Calcium Hydroxide (Ca(OH)₂) Sludge to create a sufficient yield of Calcium Chloride (CaCl₂).

Image: Environmental Solutions Asia — Spent Hydrochloric Acid; Calcium Hydroxide Sludge

Based on the lab results, our process engineers will coordinate with our Production team who prepares the acid and alkali waste for processing. Before production begins, the team will also ensure that all wastes are properly stored in the meantime.

Step 3: Physical-Chemical Treatment of Spent Acid & Sludge

Finally, the chemical waste is ready for processing. Firstly, the optimal blend of spent acid and sludge is deposited and mixed within storage tanks. Then, it is moved into bigger storage tanks, where the temperature and pH will be controlled.

Image: Environmental Solutions Asia — Storage Tanks

Thereafter, the mixture moves along to a continuous stirred tank reactor (CSTR) which aids in efficient mixing. The CSTR is corrosion resistant, which is important as spent acids may sometimes be too acidic and corrode the tank. There is also an emergency tank attached to the CSTR to handle potential liquid overflow safely.

Image: Environmental Solutions Asia — CSTR Tanks

Finally, the resultant mixture goes through a filter press. This device separates the solid precipitate from our liquid product — Calcium Chloride Solution. In addition, there is a valve within the equipment where samples can be retrieved. This allows the engineering team to adjust the ratio of the two reagents if the yield is not optimal.

Image: Environmental Solutions Asia — Filter Press

Step 4: Calcium Chloride Prepared for Sale

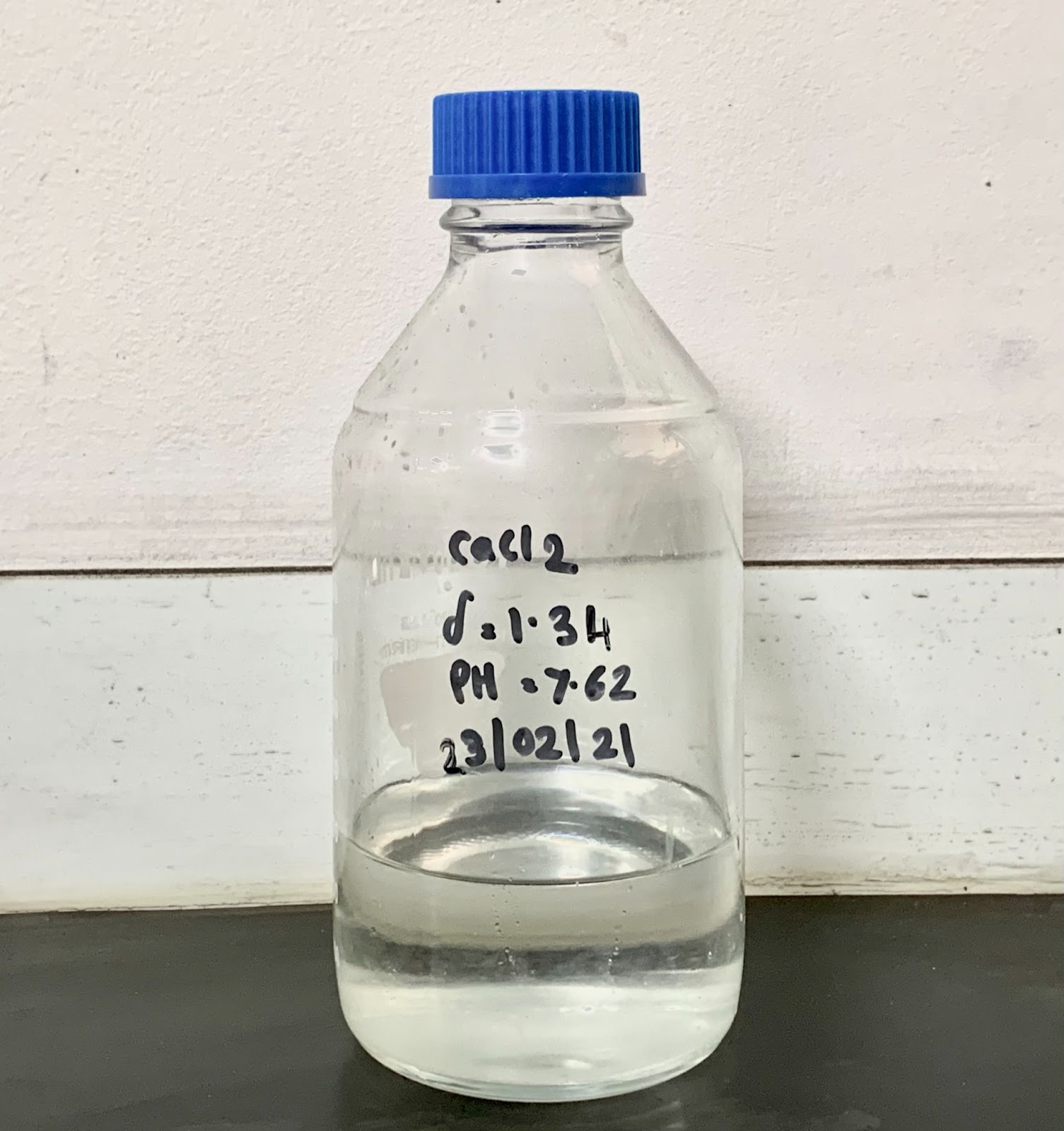

As a final step, our recycled Calcium Chloride Solution is stored into IBCs, which contains information on the origin of waste, type of waste, date of collection and processing, and net weight, ready to send off to our partners. The pharmaceutical, agricultural, construction, and petrochemical industries are common consumers of this chemical compound. This is because Calcium Chloride can be used as a drying agent for a wide range of materials, such as desiccants, road surfaces, and food preservatives. It can also be used pharmaceutically for heart treatment, or used as a reagent in wastewater treatment in the semiconductor industry.

Image: Environmental Solutions Asia — Calcium Chloride before and after going through an additional filter press to yield a sellable colorless solution.

Partner with us to enable the circular economy today.

Want to know how you can sustainably manage your spent acid and alkali waste too? We currently provide our physical-chemical processing services to partners from the Chemical, Semiconductor, Electroplating, Pharmaceutical, and Wastewater Treatment industries and more.

Get in touch with us at +65 6653 2299 (Tel), drop us an email at info@env-solutions.com, or fill in the inquiry form on our website. Alternatively, you can click here to find out more about our other services.

*Note: A spent material refers to one that has been used and contaminated, and thus cannot serve its original function. Spent acids are just one type of spent material, and are generally a mixture of nitric acid, sulfuric acid, water, and other organic compounds, and they can come from manufacturing processes that use acids.

Topics: Acid & Alkali Waste Singapore, Chemical Waste, Chemical Waste Disposal Singapore, Sustainable Waste Management Solutions Singapore

Written by Quek Leng Chuang

LengChuang is a chemical engineer and an expert in carbonomics. He is the founder and owner of Environmental Solutions (Asia) Pte Ltd.